Cut-Resistant Personal Protective Equipment (PPE) Levels Explained

Personal protective equipment (PPE) is designed to protect employees from hazards on the job. It can range from hard hats and eye protection to clothing like jackets, gloves, aprons, socks, pants, and more.

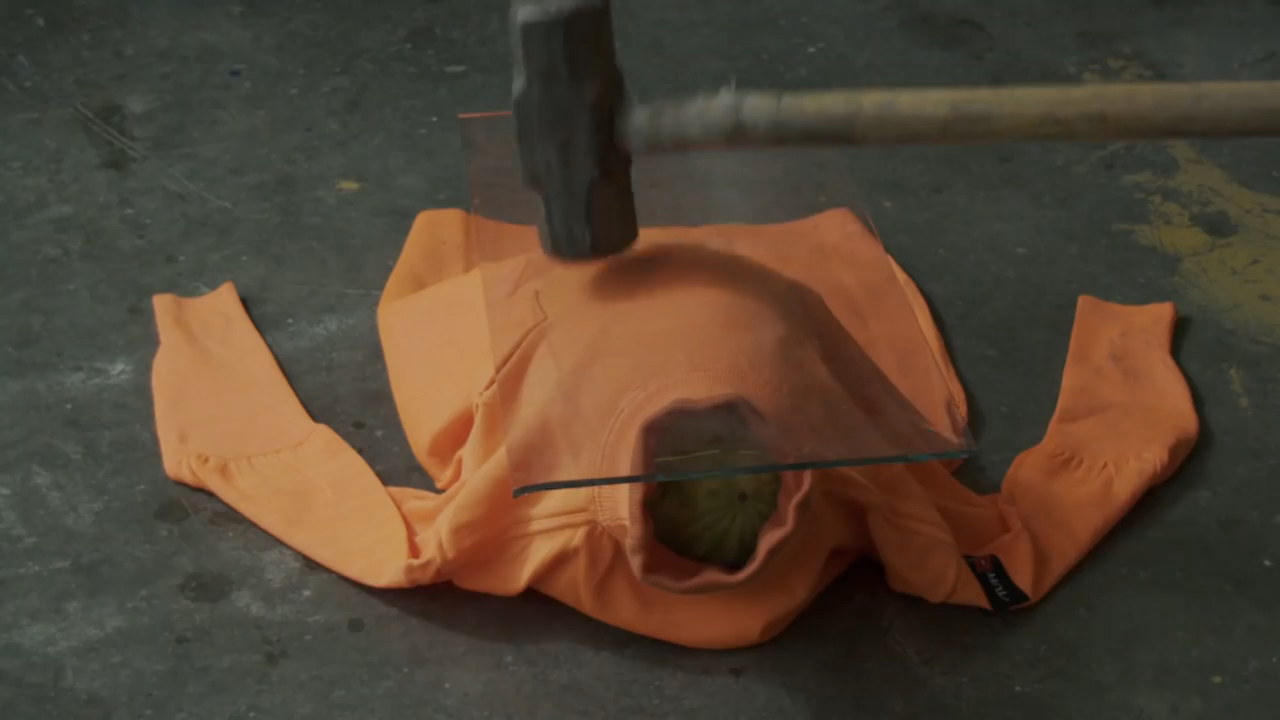

When you work in the glass-making industry or any other occupation where sharp objects are a source of concern, you need equipment that is going to keep you and your employees safe. Thankfully, cut-resistant PPE is easy to find in the online marketplace. But how do you know what level of protection is suitable for your workplace?

In this guide, the PPE experts at Tuff-N-Lite are going to break down the different levels of PPE, as well as explain how those levels are determined. By the time you finish this guide, you will have all the knowledge you need to make the most informed decision for you and your employees.

How PPE Levels are Tested & Determined

The two most prominent standards to determine PPE levels are American (US) and European (EU). Both standards have their own unique testing method, which in turn determines the level of protection.

For the American test, a razorblade is applied by a machine to the PPE material and runs back and forth until the material rips. The amount of pressure is measured in grams of force, and the result of the test determines what level of protection the product offers. There are nine levels of protection, with one being the weakest and nine being the strongest.

Now, the European test is different than the American one.

In the EU test, PPE material is still tested with a blade, but in this instance, a circular, spinning blade is used. The level is still determined by grams of force, but it is essential to understand that EU levels are not equivalent to US levels.

This is a significant misconception that must be addressed.

Demystifying the PPE Standards Misconception

The US (ASTM) and EU (EM388) levels are not parallel to one another, meaning that a US Level 4 piece of PPE does not withstand the same amount of force as an EU level 4 piece of equipment.

For example, a level 5 PPE by EU standards often turns out to be a Level 4 by US standards. Or worse, a level 4 PPE in the EU can translate to level 3 PPE in the US, which is not enough to truly serve as protective equipment, putting employees at risk.

There is also no standard conversion method, meaning that EU PPE would have to be retested in the US method to determine its true US level and vice versa.

Japan has its own test (JST) to determine protection levels, although many have now adopted the European standard.

When looking for PPE for your workplace, always be sure to check whether the equipment is US or EU level, depending on what standards you need to meet. Unfortunately, many retailers try to hide the standard to drive business. Knowing the difference yourself can save lives.

The Different Levels of Cut-Resistant PPE

Now that we’ve established how different PPE levels are determined, it’s time to look at what those levels are. We’ll be looking at the US levels, but if you’re looking for the EU levels, this is a great resource.

The US levels are based on the American Society of Testing Methods (ASTM) standard F2992/F2992M. As previously stated, there are nine levels that are each determined by grams of force, but only certain ones are useful for cut-resistance and considered PPE.

Let’s break it down.

Level 1 (A1): ≥200 grams of force

Level 2 (A2): ≥500 grams of force

Level 3 (A3): ≥1000 grams of force

Level 4 (A4): ≥1500 grams of force

Level 5 (A5): ≥2200 grams of force

Level 6 (A6): ≥3000 grams of force

Level 7 (A7): ≥4000 grams of force

Level 8 (A8): ≥5000 grams of force

Level 9 (A9): ≥6000+ grams of force

Levels 1-3 are best suited for light cut hazards. A level 1 material is equivalent to a regular cotton t-shirt, level 2 is roughly equal to a pair of denim jeans, and level 3 is comparable to a heavy canvas jacket.

When you get to levels 4-5, you are now covering for medium cut hazards. This is where real PPE starts and where you can highly reduce the likelihood of injury. Level 4 should be the baseline for your equipment.

Levels 6-9 are made for high cut hazard situations. These materials are highly resistant to even the most dangerous cuts. However, they are made with heavy material that can be stiff and not breathable, which can come with its own set of challenges.

It is important to remember that cut-resistant PPE is not a guarantee that you and your employees will be completely unharmed by cuts or scratches. This equipment is designed to protect people as much as possible and turn potentially life-threatening injuries into minor scrapes.

Wearing high-level PPE is never an excuse to act recklessly or take risks in the workplace. It is vital that you understand the threat level that the work environment you are in poses and choose your PPE accordingly.

Zones of Safety – Why They’re Important

With cut-resistant PPE, comfort and wearability can often be just as important as strength. Workers are going to be wearing these pieces of equipment all day, so ensuring that they are well-suited to their environment, hours and workload is essential.

That is why the best cut-resistant PPE feature ‘zones of safety,’ which means that certain areas have higher cut-resistance levels than others.

The purpose of this intelligent design is to balance safety with comfort.

Fatigue from hot, unbreathable, and heavy PPE clothing can actually lead to more injury and slow down the productivity of your employees.

Therefore, the areas that are most vulnerable to severe injuries – like the neck, wrists, underarms and inner legs have higher protection, while other areas have lower level PPE to make the clothing more comfortable.

At Tuff-n-lite, we consider the most vulnerable areas to cuts and increase the PPE level of fabric in that area, while the rest of the jacket might be a level 4 to make it lighter and more breathable.

With zones of safety raising and lowering the levels of resistance in certain areas, PPE can ensure protection for those wearing it without sacrificing comfort and wearability.

Evaluate Threat Levels In the Workplace

The first question you should ask when choosing the right PPE is, “What is the level of threat my employees are exposed to on the job?”

For example, if they are handling glass that is:

- ½ inch or more

- Large lites (i.e. 10’ by 13’ lites of glass)

- Heavy annealed glass that can shatter into sharp spikes and be as sharp as a scalpel

- Handling glass above the head

- Stocing

- Moving glass up and down stairs (manufacturing process)

Then putting your employees in level 9 PPE is going to protect them the best. Although it may not be as comfortable, it can save their lives in bad situations.

On the other hand, if they are dealing with tempered glass that is ¼ in thick, their risk is much lower for injury and levels 4-5 PPE would be a good fit.

Watch this video to find out who we are, what we believe in, and how our Tuff-N-Lite equipment will keep you safe!

Why Cut-Resistant PPE Levels Matter

When in high-risk work environments, a reliable set of cut-resistant PPE is essential. Likewise, knowing what level of resistance is right for your work environment will help you ensure you can protect your employees and follow proper safety standards.

Now that you’ve read this guide, you have a strong understanding of PPE levels, how they are determined, and why the difference between them is crucial. With all this information in mind, you are now able to make the most informed decision possible when it comes to selecting the right PPE for your workplace.

Still Have Questions?

If you need assistance making the right decision, our team at Tuff-N-Lite would be happy to help you understand what PPE is needed in your particular workplace. Please contact us.